PRODUCT PARAMETER

|

Model

|

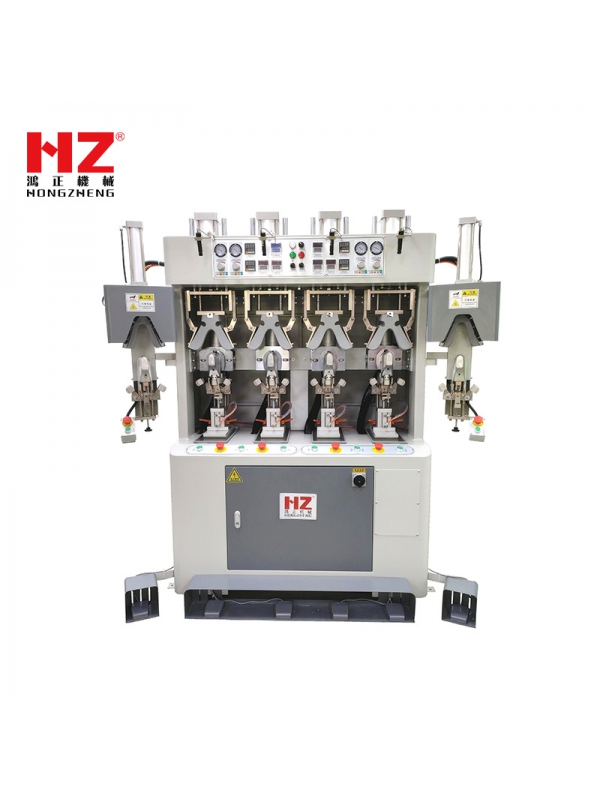

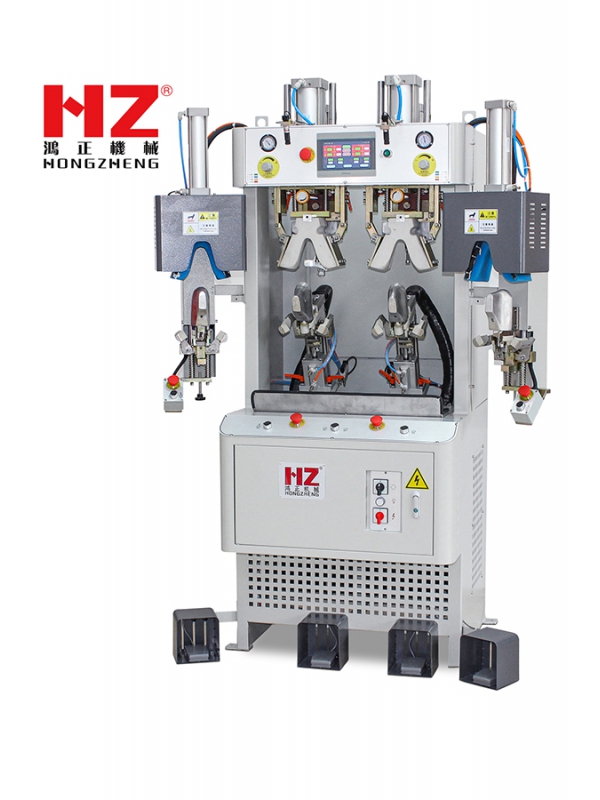

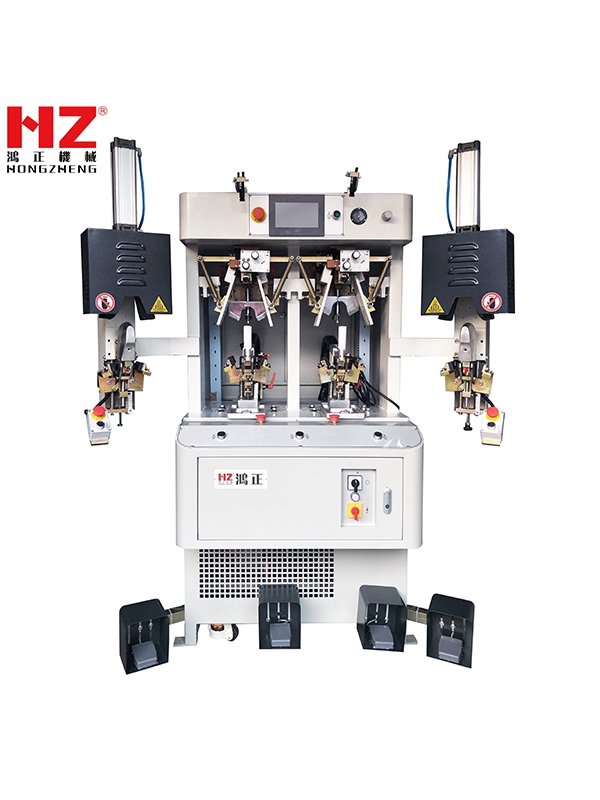

HZ-662E-4C2H(Airbag model)

|

|

Machine Dimensions

|

1380*760*1950mm

|

|

Packaging Size

|

1430*810*2080mm

|

|

Net Weight

|

400kg

|

|

Air Source

|

6Bra

|

|

Power

|

2.7KW

|

|

Daily Difference Double

|

1500-1800pair

|

Double Cold and Double Hot Heel Shaping Machine

The footwear industry has witnessed great advances in technology in the past few years. One of the latest innovations is the Double Cold and Double Hot Heel Shaping Machine. This machine is designed to shape the heels of shoes and provide a perfect finish. In this article, we will take a closer look at this revolutionary machine and discuss its key features and benefits.

Key Features

The Double Cold and Double Hot Heel Shaping Machine has several notable features that set it apart from other machines in the market. One of its key features is the double heating system. This system allows the machine to carry out both cold and hot shaping. The cold shaping feature is used to shape heels made of materials that tend to shrink when exposed to heat. The hot shaping feature, on the other hand, is used to shape heels made of materials that easily deform when exposed to heat. The combination of these two features provides a unique solution that meets the needs of a wide range of materials.

Another important feature of the Double Cold and Double Hot Heel Shaping Machine is its ease of use. The machine is user-friendly and comes with an easy-to-follow manual. Operators do not require any special skills to use the machine. This means that even new operators can use the machine with minimal supervision.

Benefits

The Double Cold and Double Hot Heel Shaping Machine offers several benefits to manufacturers. The first benefit is increased productivity. The machine is designed to work fast and can shape multiple heels simultaneously. This means that manufacturers can produce more shoes in a shorter time.

The second benefit is improved quality. The machine provides a consistent and accurate finish, ensuring that all shoes come out perfectly shaped. This boosts the quality of shoes, making them more attractive to customers.

The third benefit is cost savings. The machine is energy-efficient and does not consume a lot of power. This results in lower energy bills for ma